Interested in our premium pump solutions? Reach out to us today for a free consultation and a customized quote. Our dedicated team of experts is here to offer in-depth expertise and guide you to the ideal solution for your needs.

Alternatively, you can use our inquiry form.

The pumps are suitable to transfer liquids containing impurities measuring up to 2-3 mm. The hydraulic components, namely the impeller and scroll in PBT and the cast iron pump body allow the pumps to be used with water, emulsions and oily substances in general with a maximum viscosity of 3° Engler (21 CST).

The temperature of the liquid must not exceed 70° C.

They are usually used on:

• Machine tools (milling machines – lathes - drills)

• Surface treatment systems

• Filtration systems

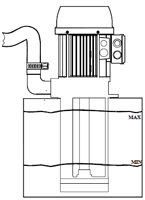

They should usually be installed on a tank, with a capacity in proportion to the flow rate, at about 3 – 4 cm. from the bottom. It is important to check that the maximum level of the liquid in the tank always remains 3 – 4 cm. lower than the flange (see figure). In cases where the liquid is particularly dirty, the user is recommended to construct the tank in compartments to allow the dirt to deposit before it is stirred up by the pump.

For other usages you are advised to consult our technical office

| Components | SP | auf Anfrage |

| Pump body | Cast iron G 20 | - |

| Pumpendeckel | PBT* |

Cast iron G 20 |

| Impeller |

PBT* | Cast iron G 20 |

| Shaft | Stahl C40 | AISI 420 |

| type | kW | H = Total head in metres of column of water | |||||||||||||

| input | nom. | 0 | 0,5 | 1 | 1,5 | 2 | 2,5 | 3 | 3,5 | 4 | 4,5 | 5 | 5,5 | 6 | |

| P1 | P2 | Q = Delivery l/min | |||||||||||||

| SP 12 | 0,15 | 0,07 | 65 | 61 | 57 | 52 | 47 | 41 | 35 | 29 | 21 | 12 | |||

| SP 18 | 0,17 | 0,09 | 75 | 71 | 67 | 58 | 53 | 48 | 42 | 35 | 28 | 18 | 6 | ||

| SP 25 | 0,26 | 0,18 | 85 | 81 | 77 | 72 | 68 | 63 | 58 | 52 | 46 | 38 | 30 | 19 | 5 |

| SP 33 | 0,36 | 0,25 | 87 | 84 | 80 | 76 | 71 | 67 | 62 | 56 | 50 | 44 | 36 | 26 | 11 |

| type | kW | H = Total head in metres of column of water | ||||||||||||||

| input | nom. | 0 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 12 | 13 | 14 | |

| P1 | P2 | Q = Delivery l/min | ||||||||||||||

| SP 50 | 1 | 0,75 | 288 | 271 | 251 | 234 | 215 | 194 | 172 | 150 | 125 | 100 | 70 | |||

| SP 75 | 1,2 | 0,9 | 320 | 304 | 289 | 272 | 254 | 236 | 216 | 195 | 172 | 147 | 120 | 55 | ||

| SP 100 | 1,41 | 1,1 | 340 | 326 | 310 | 292 | 275 | 255 | 236 | 216 | 195 | 171 | 144 | 114 | 79 | 40 |

| SP 150 | 1,86 | 1,5 | 400 | 380 | 358 | 337 | 317 | 296 | 273 | 246 | 219 | 188 | 148 | 107 | 62 | 18 |

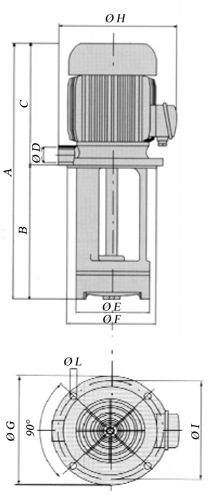

| type | Dimensions (mm) | weight |

|||||||||

| A | B | C | Ø D | Ø E | Ø F | G | H | Ø I | Ø L | kg | |

| SP 12 | 265 | 90 T | 165 | ¾" | 98 | 100 | 130 | 151 | 115 | 7 |

5 |

| 285 | 120 T | 5,3 | |||||||||

| 335 | 170 T | 5,5 | |||||||||

| 385 | 220 T | 5,7 | |||||||||

| 435 | 270 T | 6 | |||||||||

| 515 | 350 | 6,5 | |||||||||

| SP 18 | 265 | 90 T | 165 | ¾" | 98 | 100 | 130 | 151 | 115 | 7 (n.4) |

5,1 |

| 285 | 120 T | 5,4 | |||||||||

| 335 | 170 T | 5,6 | |||||||||

| 385 | 220 T | 5,7 | |||||||||

| 435 | 270 T | 6 | |||||||||

| 515 | 350 | 6,6 | |||||||||

| SP 25 | 305 | 90 T | 215 | ¾" | 98 | 100 | 130 | 170 | 115 | 7 (n.4) |

6,5 |

| 335 | 120 T | 6,8 | |||||||||

| 385 | 170 T | 7,1 | |||||||||

| 435 | 220 T | 7,2 | |||||||||

| 485 | 270 T | 7,5 | |||||||||

| 565 | 350 | 8,1 | |||||||||

| SP33 | 305 | 90 T | 215 | ¾" | 98 | 100 | 130 | 170 | 115 | 7 (n.4) |

7,1 |

| 335 | 120T | 7,3 | |||||||||

| 385 | 170 T | 7,5 | |||||||||

| 435 | 220 T | 7,7 | |||||||||

| 485 | 270 T | 8 | |||||||||

| 565 | 350 | 8,6 | |||||||||

| SP50 | 450 | 200 T | 250 | 1¼" | 138 | 140 | 180 | 215 | 160 | 9 (n.4) |

13,5 |

| 520 | 270 T | 14,2 | |||||||||

| 600 | 350 | 15 | |||||||||

| 690 | 440 | 15,9 | |||||||||

| 800 | 550 | 17 | |||||||||

| SP 75 | 450 | 200 T | 250 | 1¼" | 138 | 140 | 180 | 215 | 160 | 9 (n.4) |

14,5 |

| 520 | 270 T | 15,2 | |||||||||

| 600 | 350 | 16 | |||||||||

| 690 | 440 | 16,9 | |||||||||

| 800 | 550 | 18 | |||||||||

| SP 100 | 500 | 200 T | 300 | 1¼" | 138 | 140 | 180 | 230 | 160 | 9 (n.4) |

16,3 |

| 570 | 270 T | 17,1 | |||||||||

| 650 | 350 | 18,1 | |||||||||

| 740 | 440 | 19,1 | |||||||||

| 850 | 550 | 20,3 | |||||||||

| SP 150 | 500 | 200 T | 300 | 1¼" | 138 | 140 | 180 | 230 | 160 | 9 (n.4) |

17,6 |

| 570 | 270 T | 18,4 | |||||||||

| 650 | 350 | 19,3 | |||||||||

| 740 | 440 | 20,1 | |||||||||

| 850 | 550 | 21,9 | |||||||||