Interested in our premium pump solutions? Reach out to us today for a free consultation and a customized quote. Our dedicated team of experts is here to offer in-depth expertise and guide you to the ideal solution for your needs.

Alternatively, you can use our inquiry form.

Do you need help replacing your pump? Do you need spare parts? Our support team will help you. How to contact us.

technik-vertrieb@linn-pumpen.de +49 2355 902929 Jetzt Unterstützung anfordern

Self priming Pumps with flexible impeller are fast and easy to operate. Self priming AISI 304 and 316L stainless steel pumps with flexible impeller for thick and thin liquids.

The main feature of these pumps is their

strenght, due to the process throught

which they are manufactured, that is to

say stainless steel casting.

The total absence of junctions or welding

give to the material a high resistance to

abrasion and corrosion.

They feature thick walls (4-5 mm) and

smooth surface.

Mag pumps are suitable for whatever

industrial sector and they are suitable for

trasferring liquids gently without

emulsifyng the product.

Instant priming up to 4 - 5 meters. Pumping

works in both directions of rotation.

Suitable for thick liquids containing floating

bodies.

Mechanical seal is supplied according to

the product to be pumped.

The pumps are coupled to the electric

motor in compliance with CE standard.

Flexible Impellers

In Neoprene, Nitrile Rubber,

Nitrile Rubber AL, Dutral or Silicone

according to the product to be pumped.

The impellers are temperature resistant

up 100° C.

Chemistry,

Galvanization,

Pharmaceutical,

Mechanics

• Saline water

• Galvanic solutions

• Various acids and alkalies

• Inks and dyes

• Latex, H20 based glues

• Creams, detergents

• Liquid soaps, shampoos • Stareh, lotions

• Dressings, liquid detergents

• Emulsifiable water • Plasticizers

• Dyes, various oils

• Toothpastes

Purification plants

• Water with sludge

• Acid or basic water

• Dirty water with suspended bodies

Environmental protection

• General drainage

• Spent mineral and vegetable oils

• Untreated waters and sewage

• Process developing waste

• Toxic and noxious liquids

Agriculture,

Foodstuffs

• Wine and concentrated must

• Fruit juice

• Tomato sauce

• Vegetable oils, grease

• Milk, condensed milk

• Whey, yogurt, cream

• Jelly, honey, mustard, molasses

• Flavours, beer

• Extracts and syrups

• Vinegar

• Jam

• Brine

• Skimming yeast from fermentations

Some good reasons to use MAG pumps:

-Easy to use - Easy to dismantle and to clean

- Bottom valve is not necessary

- No maintenance required: dismontable by anyone with a wrench.

- Pump needs not be filled

NOTE: do not pump petroline, thinners, solvents or aggressive acids .

Mechanical seal variations:

Carbon-ceramic·NBR

Carbon-ceramic·FPM

Carbon-chrome steel·NBR

Carbon-chrome steel·FPM

silicon carbide-silicon carbide-NBR

Version A = handle + switch + cable 5 m

for models 11 - 22 - 33 - 44 - 55

(reverser supplied on request)

Version C = for stationary installation

Version B (1~)= truck + switch + cable 5 m

for models 22 - 33 - 44 - 55

(reverser supplied on request)

Version B (3~)= truck + switch + cable 10m

for models 62 - 66 - 77 - 88 - 99

(reverser supplied on request)

| Typ | kW | A | H = TOTAL HEAD IN METERS | OPENINGS Ø | PIPE FITIING | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 5 | 10 | 15 | 20 | 25 | ||||||

| Q = Capacity in litres/minutes (when used with water) +/- 5% | |||||||||||

| MAG11M4 | 0,25 | 2,1 | Q | 14 | 12 | 9 | 5 | 1 | - | 1/2" | 1/2" x 13 |

| MAG11T4 | 0,25 | 0,9 | 14 | 12 | 9 | 5 | 1 | - | 1/2" | 1/2" x 13 | |

| MAG22M4 | 0,37 | 3,2 | 40 | 38 | 34 | 30 | 24 | 16 | 3/4" | 3/4" x 20 | |

| MAG22T4 | 0,37 | 1,2 | 40 | 38 | 34 | 30 | 24 | 16 | 3/4" | 3/4" x 20 | |

| MAG33M4 | 0,75 | 6 | 79 | 73 | 66 | 57 | 47 | 30 | 1" | 1" x 25 | |

| MAG33T4 | 0,75 | 2,1 | 79 | 73 | 66 | 57 | 47 | 30 | 1" | 1" x 25 | |

| MAG44M4 | 1,1 | 7,8 | 120 | 112 | 102 | 88 | 74 | 54 | 1¼" | 1¼" x 30 | |

| MAG44T4 | 1,1 | 3,0 | 120 | 112 | 102 | 88 | 74 | 54 | 1¼" | 1¼" x 30 | |

| MAG55M4 | 1,5 | 10,5 | 165 | 155 | 142 | 127 | 110 | 88 | 1½" | 1½" x 40 | |

| MAG55T4 | 1,5 | 4,0 | 165 | 155 | 142 | 127 | 110 | 88 | 1½" | 1½" x 40 | |

| MAG62M4 | 2,6 | 17 | 200 | 190 | 175 | 150 | 130 | 110 | 1½" | 1½" x 40 | |

| MAG62T4 | 2,2 | 6 | 200 | 190 | 175 | 150 | 130 | 110 | 1½" | 1½" x 40 | |

| MAG66M4 | 2,6 | 17 | 350 | 340 | 320 | 300 | 280 | 260 | 2" | 2" x 50 | |

| MAG66T4 | 2,2 | 6 | 350 | 340 | 320 | 300 | 280 | 260 | 2" | 2" x 50 | |

| MAG77T4 | 4 | 10 | 470 | 450 | 430 | 400 | 380 | 360 | 2½" | 2½" x 60 | |

M = Single-phase motor 230 volt 50 HZ T = Three-phase motor 400 volt 50 HZ

| Typ | kW | A | H = TOTAL HEAD IN METERS | OPENINGS Ø | PIPE FITIING | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 5 | 10 | 15 | 20 | 25 | ||||||

| Q = Capacity in litres/minutes (when used with water) +/- 5% | |||||||||||

| MAG11M6 | 0,25 | 2 | Q | 10 | 9 | 4 | - | - | - | 1/2" | 1/2" x 13 |

| MAG11T6 | 0,25 | 1,1 | 10 | 9 | 4 | - | - | - | 1/2" | 1/2" x 13 | |

| MAG22M6 | 0,25 | 2 | 30 | 27 | 24 | 21 | 17 | 13 | 3/4" | 3/4" x 20 | |

| MAG22T6 | 0,25 | 1,1 | 30 | 27 | 24 | 21 | 17 | 13 | 3/4" | 3/4" x 20 | |

| MAG33M6 | 0,55 | 4,5 | 57 | 53 | 47 | 41 | 33 | 24 | 1" | 1" x 25 | |

| MAG33T6 | 0,55 | 2,1 | 57 | 53 | 47 | 41 | 33 | 24 | 1" | 1" x 25 | |

| MAG44M6 | 0,75 | 5 | 84 | 75 | 64 | 52 | 39 | 24 | 1¼" | 1¼" x 30 | |

| MAG44T6 | 0,75 | 2,5 | 84 | 75 | 64 | 52 | 39 | 24 | 1¼" | 1¼" x 30 | |

| MAG55M6 | 1,1 | 7,5 | 117 | 108 | 96 | 82 | 67 | 50 | 1½" | 1½" x 40 | |

| MAG55T6 | 1,1 | 3,6 | 117 | 108 | 96 | 82 | 67 | 50 | 1½" | 1½" x 40 | |

| MAG62M6 | 1,8 | 12 | 145 | 135 | 120 | 100 | 80 | 60 | 1½" | 1½" x 40 | |

| MAG62T6 | 1,5 | 4,8 | 145 | 135 | 120 | 100 | 80 | 60 | 1½" | 1½" x 40 | |

| MAG66M6 | 1,8 | 12 | 240 | 222 | 200 | 180 | 160 | 140 | 2" | 2" x 50 | |

| MAG66T6 | 1,5 | 4,8 | 240 | 222 | 200 | 180 | 160 | 140 | 2" | 2" x 50 | |

| MAG77T6 | 2,2 | 5,6 | 300 | 285 | 265 | 240 | 215 | 185 | 2½" | 2½" x 60 | |

| MAG88T6 | 3 | 7,3 | 540 | 520 | 490 | 420 | 370 | 300 | 2½" | 2½" x 60 | |

M = Single-phase motor 230 volt 50 HZ T = Three-phase motor 400 volt 50 HZ

| Typ | kW | A | H = TOTAL HEAD IN METERS | OPENINGS Ø | PIPE FITIING | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 5 | 10 | 15 | 20 | 25 | ||||||

| Q = Capacity in litres/minutes (when used with water) +/- 5% | |||||||||||

| MAG22T8 | 0,25 | 1,3 | Q | 21 | 20 | 18 | 15 | 12 | - | 3/4" | 3/4" x 20 |

| MAG33T8 | 0,35 | 1,8 | 40 | 36 | 31 | 25 | 19 | 12 | 1" | 1" x 25 | |

| MAG44T8 | 0,55 | 2,4 | 63 | 58 | 57 | 44 | 30 | - | 1¼" | 1¼" x 30 | |

| MAG55T8 | 0,75 | 2,7 | 80 | 74 | 66 | 58 | 47 | 35 | 1½" | 1½" x 40 | |

| MAG62T8 | 1,5 | 5 | 110 | 95 | 80 | 65 | 50 | 30 | 1½" | 1½" x 40 | |

| MAG66T8 | 1,5 | 5 | 152 | 140 | 124 | 108 | 92 | 76 | 2" | 2" x 50 | |

| MAG77T8 | 1,5 | 5 | 235 | 220 | 200 | 180 | 158 | 135 | 2½" | 2½" x 60 | |

| MAG88T8 | 3 | 9 | 420 | 400 | 380 | 360 | 300 | 240 | 2½" | 2½" x 60 | |

| MAG99T8 | 4 | 10,5 | 600 | 550 | 480 | 400 | 320 | 250 | 3" | 3" x 75 | |

T = Three-phase motor 400 volt 50 HZ

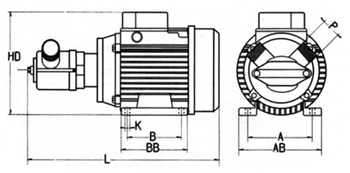

| Typ | Dimensions | ||||||||

| rpm | A | AB | B | BB | L | K | HD | P | |

| MAG11 | 1400 | 100 | 120 | 80 | 100 | 250 | 7 | 160 | ½" |

| 920 | 125 | 153 | 100 | 124 | 330 | 7 | 190 | ||

| MAG22 | 1400 | 112 | 136 | 90 | 112 | 330 | 7 | 168 | ¾" |

| 920 700 |

125 | 153 | 100 | 124 | 330 | 7 | 190 | ||

| MAG33 | 1400 920 700 |

125 | 153 | 100 | 124 | 330 | 7 | 190 | 1" |

| MAG44 | 1400 920 700 |

140 | 170 | 100 | 131 | 390 | 10 | 207 | 1¼" |

| MAG55 | 1400 920 700 |

140 | 170 | 125 | 156 | 420 | 10 | 207 | 1½" |

| MAG62 | 1400 920 700 |

160 | 192 | 140 | 163 | 460 | 12 | 235 | 1½" |

| MAG66 | 1400 920 700 |

160 | 192 | 140 | 163 | 460 | 12 | 235 | 2" |

| MAG77 | 1400 920 700 |

190 | 220 | 140 | 182 | 530 | 12 | 260 | 2½" |

| MAG88 | 920 | 216 | 260 | 140 | 181 | 550 | 12 | 320 | 2½" |

| 700 | 216 | 260 | 178 | 219 | 590 | 12 | 320 | ||

| MAG99 | 700 | 216 | 260 | 178 | 219 | 650 | 12 | 320 | 3" |